Perhydropolysilazane (PHPS) or Inorganic Polysilazane IOTA-PHPS

Description:

The coating product is mainly composed of perhydropolysilazane IOTA PHPS,diluted and stored in a solvent.

Name: Hydrophilic Super Hard Stain Resistant Nano-Coating Materials

English synonyms: PHPS

Polysilazane Liquid Coating Materials

Features:

Good adhesion on the metal ceramic polymer materials

Can be converted to SiO2 at a lower temperature

Short curing time

Curing a variety of ways

Good solubility

Technical Parameters:

Appearance: colorless transparent liquid

Solid content: 20%

Solvent: butyl ether

Liquid density: 1.16-1.31 g / ml

Density after curing: 1.6-2.0 g / ml

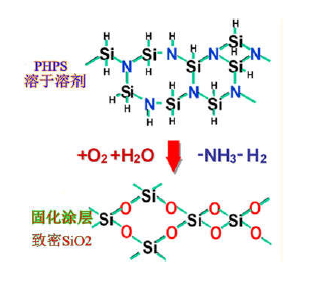

Curing mechanism:

The curing of the coating material mainly is the Si-N bond hydrolysis, the mechanism is as follows:

![]()

Curing conditions:

Room temperature: more than 7 days

Moisture curing: humidity 90%, temperature 150 ℃, 2h

Coating properties:

Coating thickness (nm): >100

Composition: SiOx

Hardness (GPa): 3 (ammonia curable)

8-10 (high temperature curing)

Elastic modulus (GPa): 60 (NH3.H2O curing)

100-130 (high temperature curing)

Pencil Hardness: 9H(Chinese)

6H (Mitsubishi)

Adhesion (grid method): 0 level

Transparency (visible light): > 90%

Temperature resistance (air): 800 ℃

Acid (10% hydrochloric acid): about a month.

Rust, alkali, salt water resistance

Applications:

Building anti - graffiti

electronic circuit

Semiconductor insulating layer

Metal high temperature oxidation resistance

Plastic packaging waterproof gas barrier

Metal anti-corrosion

Surface hardening coating

How to use:

First, clean the substrate surface, coating products using spin-coating, rubbing, spraying, dipping, etc. construction, and then by room temperature curing, high temperature curing, etc. curing.

Clean:

Proper cleaning is important. After using promptly use acetone or solvent oil to wipe the tool cleaning.IOTA PHPS cured, the solvent can not be washed away.

Product packaging:

According to customer demand, 0.5-10 liters metal sealed drum, generally use xylene, dibutyl ether or dichloromethane for filling, solid content of 2-20%.

Storage:

Store at low temperatures below 10 ℃.

Unopened IOTA PHPS, shelf life: 6 months.

After opening, use up IOTA PHPS as soon as possible according to the actual situation.

Precautions:

Should l be in a ventilated, dry environment, and the use of necessary protective measures, such as gloves, masks, goggles;

Do not place uncured IOTA PHPS near to fire, humid air, or water.

After opening, seal it in a timely manner. If it is used in a humid environment, replace the container with nitrogen after using.