Hits: 488 img

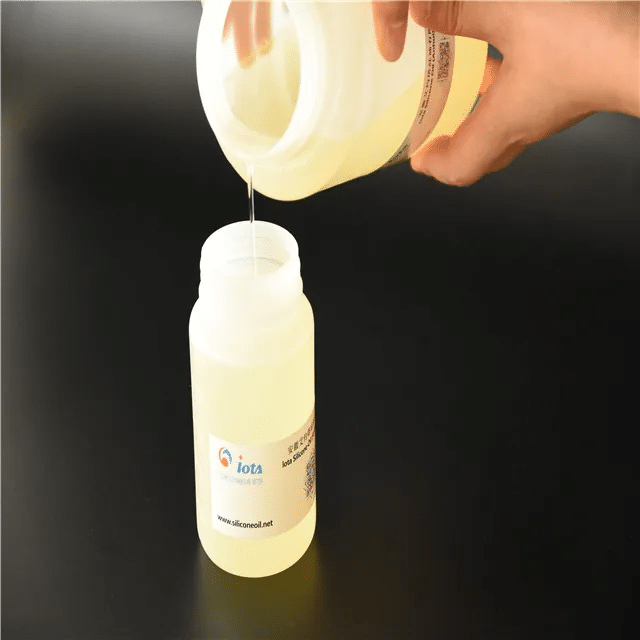

In the pursuit of exceptional coating performance, IOTA 9118 Organic Polysilazane stands out as a shining star in the field of high-temperature coating systems. This liquid polysilazane, also known as a ceramizable precursor polymer, is specifically designed for high-temperature coating systems, boasting low viscosity, high adhesion, and other outstanding properties.

IOTA 9118 can be easily applied to various substrates, including metals, alloys, glass, paint films, and plastics (such as PP, PC, PVC, PMMA), through methods like coating, dip coating, spray coating, and brush coating. The resulting coating is heat-resistant, oxidation-resistant, corrosion-resistant, non-flammable, with a high hydrophobic angle (100°-105°), and excellent transparency (>95% for visible light), and adhesion (Grade 0) to metals.

IOTA 9118 finds applications in a wide range of fields, including coatings, adhesives, non-flammable composites, polymer matrix composites, glass and grinding tool industries, as well as areas requiring low surface tension and easy cleaning. Its technical parameters are superior, with a moderate molecular weight, purity exceeding 99%, and density and viscosity meeting high standards.

In terms of curing methods, IOTA 9118 offers both thermal curing and UV curing options, catering to different application scenarios. After pyrolysis, IOTA 9118 can be converted into amorphous or crystalline ceramics, with the product composition closely related to the pyrolysis atmosphere, demonstrating high flexibility and customizability.

Choose IOTA 9118 for efficient, durable, and reliable high-temperature coating solutions. Let's collaborate to inject new vitality and possibilities into the field of high-temperature material protection!